Positions, Policies and Milestones

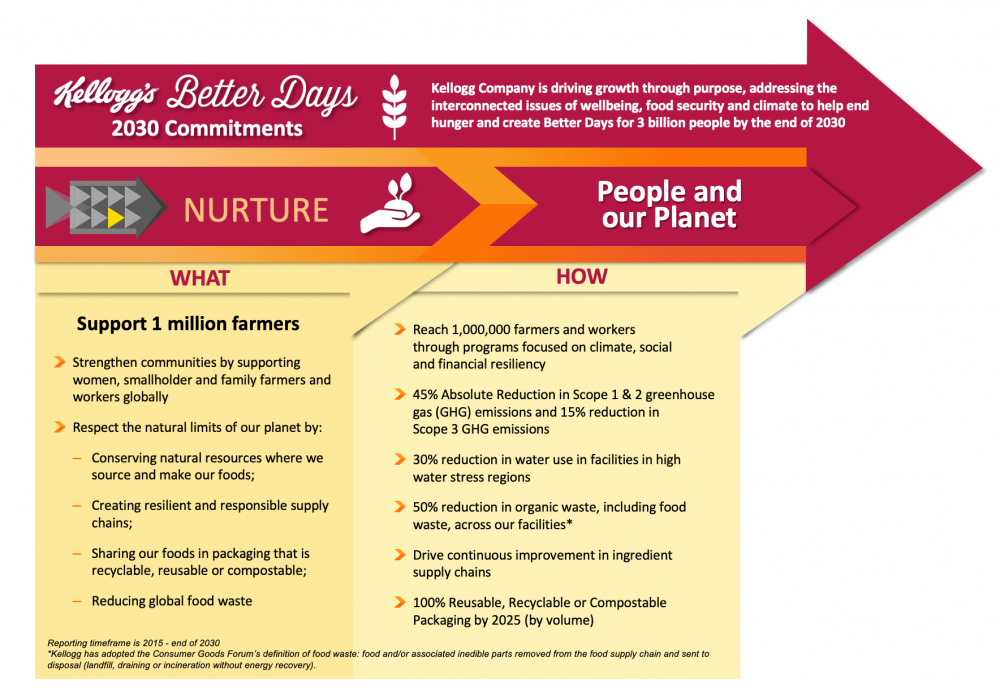

Through our Kellogg’s® Better Days commitment, we are strengthening communities by supporting 1 million farmers, especially women smallholders and workers globally while respecting the natural limits of our planet by:

- Conserving natural resources all along our value chain;

- Creating resilient and responsible supply chains;

- Sharing our foods in packaging that is recyclable, reusable or compostable; and

- Reducing global food waste

REACH 1,000,000 FARMERS AND WORKERS THROUGH PROGRAMS FOCUSED ON CLIMATE, SOCIAL AND FINANCIAL RESILIENCY

Kellogg partners with a variety of suppliers, NGOs, research groups and others to provide training and/or technical assistance that contributes to:

- Improved climate smart agricultural practices, including addressing yields, deforestation, and GHG emissions;

- Social benefits, including human rights and diversity programs; and

- Financial resiliency, including capability to sustain during periods of economic and environmental stress.

Kellogg tracks and reports the numbers of farmers and workers engaged by participation in training on any of the above topics, receipt of technical assistance or inputs, receipt of funding, or receipt of other educational resources to help change agricultural, business or financial practices. Each participant will be tracked as one (1) person engaged.

45% ABSOLUTE REDUCTION IN SCOPE 1 & 2 GHG EMISSIONS AND 15% REDUCTION IN SCOPE 3 GHG EMISSIONS

In 2008, Kellogg committed to reducing our normalized energy usage and greenhouse gas (GHG) emissions 15-20% by 2015 (from a 2005 baseline). In 2014, Kellogg built on our 2008 sustainability commitments with new goals in two areas: responsible sourcing and natural resource conservation, which included targets to reduce energy and GHG emissions by an additional 15% (per metric ton of food produced) and expand the use of low-carbon energy in our plants by 50% by 2020 from our 2015 performance. From 2005 – 2015, we have already delivered Scope 1 and 2 absolute emissions reductions from manufacturing of approximately 12%.

In 2015, we went a step further to commit to Science Based Targets to deliver a Scope 1 and 2 target of 65% reduction and Scope 3 target of 50% reduction by 2050. These targets must be coordinated and executed across national and geographic boundaries, in more than 20 countries of the world, and across suppliers with varying levels of resourcing and expertise. Kellogg created a detailed glide path to enable and track execution with key milestones. Our Kellogg’s® Better Days commitment of 45% absolute reduction in Scope 1 & 2 GHG emissions and 15% reduction in Scope 3 GHG emissions from our 2015 baseline is the next step in our journey to reach our Science-Based Targets.

GHG emissions will be measured and aligned to the guidance outlined in the WBCSD GHG Protocol and third-party verified annually.

30% REDUCTION IN WATER USE IN FACILITIES IN HIGH WATER STRESS REGIONS

In 2008, Kellogg committed to reducing our normalized water usage by 15-20% by 2015 (from a 2005 baseline) and by 2014, we set new commitments to reduce water use by an additional 15% (per metric ton of food produced) and increase water reuse in our facilities. Although we have made significant progress on these commitments, we believe that we haven’t made enough progress in our areas of highest water risk. Therefore in our new Kellogg’s® Better Days commitment, we are focused on setting targets based on localized risk as identified through internal and external assessments.

Determining Water Risk

We developed a global water risk assessment in 2014 and updated it in 2018 in partnership with an external consultant. Fifty-three (53) of the fifty-seven (57) global manufacturing sites were included in the study. Sites were prioritized based upon internal rating (an average score from survey questions covering current and future risks for physical; regulatory; and social/reputational) and external rating (an average score calculated from core WRI Aqueduct Indicators). Ratings were calculated for current and future trend (3-5 years) conditions. The assessment identified 20 of 53 sites as high risk [Mexico (3), USA (9), Australia (1), India (2), Belgium (1), South Korea (1), Malaysia (1), and Egypt (2)]. Eleven (11) sites had a high-risk internal score, indicating that they have ‘self-identified’ that local, site level water risks exist. Twelve (12) sites had a high-risk external score, suggesting that they should be on a “watch list” for changing conditions and further evaluated to ensure that the “local” perspective is properly assessed. Three (3) sites had both internal and external ratings above the thresholds. The assessment also projected that four (4) sites may join the current 20 high risk sites in the next five (5) years, as water stress trends increase in Russia and Spain.

Measurement

Site-specific water use targets for the high risk facilities will be developed in alignment with water reduction action plans. The water consumption of the sites will be monitored through our KCAPP (Kellogg Cares About People and Planet) data management system (starting in 2020 the new INSIGHT data management system will be used for this purpose).

50% REDUCTION IN ORGANIC WASTE ACROSS OUR FACILITIES

In 2008, Kellogg committed to reducing our normalized waste to landfill 15-20% by 2015 (from a 2005 baseline). By the end of 2009, we had exceeded the waste to landfill goal (with a 41.5% reduction from the 2005 baseline), so we revised the goal to decrease waste to landfill by an additional 20% from 2009 to 2015. In our Global Sustainability Commitments, announced in 2014, we set out to ensure 30% of our plants send zero waste to landfill by 2016, and to reduce total waste in our plants by 15% by 2020, with a focus on food waste. At the end of 2018, our normalized waste to landfill shows an increase of 10%, but thanks to our actions we have reduced normalized total waste by 6.7% against our 2015 baseline and absolute organic waste shows a decrease of 12% since 2016.

We recognize that organic waste plays an important role in food security and climate change. We are shifting our focus to deliver a 50% reduction in organic waste across our facilities to target our largest area of waste. We measure and report our food waste in conformance with the Food Loss Waste (FLW) Protocol. The FLW Protocol allows an entity to choose the combination of materials and destinations it considers to be “food loss and waste.” Kellogg’s definition of “food loss and waste”, which we label as “organic waste," extends to all organic waste lost in our facilities. This includes the materials under the following eight (8) destination categories (of the 10 in the FLW Standard): Animal feed, bio-based materials/biochemical processing, codigestion/anaerobic digestion, composting/aerobic processes, controlled combustion, land application, landfill, and sewer/wastewater treatment.

DRIVE CONTINUOUS IMPROVEMENT IN INGREDIENT SUPPLY CHAINS

Kellogg has been committed to responsibly sourcing its priority ingredients and support agriculture, which is smart for our climate and smart for the growers, since 2014. We have made tremendous progress on our journey to responsible sourcing across our rice, wheat, corn, potatoes, sugar beets, sugar cane, cocoa, palm oil, fruits (including strawberry and raisins/sultanas) and vanilla supply chains. Through these efforts, we’ve reached thousands of farmers and seen improvements in transparency and sustainability.

Through this journey, we have better understood the dynamic nature of our supply chains and our business. Although some of the priority ingredients that we selected in 2014 are still at the core of our business – like corn, wheat, rice and potatoes – others have had significant decreases in volumes due to divestiture or shifts in strategy. Similarly, new ingredients have come become more material to our business as we grow in emerging markets and acquire new businesses.

With this in mind, we are shifting our approach to focus on the most material ingredients. Our list of priority ingredients may change between now and 2030 as we regularly reassess materiality based on:

- Global volume

- Global spend

- Environmental risk

- Social risk

- Proximity to brand

A summary of our materiality assessment will be posted annually as part of our responsible sourcing milestones. We will measure continuous improvement in these supply chains through one or more of the following:

- Input optimization

- Biodiversity

- Water use and quality

- Energy / greenhouse gas emissions

- Soil health

- Climate resiliency

- Human and worker rights

Kellogg will measure this through the Kellogg Grower Survey, or industry standard tools like Field to Market’s Fieldprint® Calculator, Sustainable Agriculture Initiative’s Farmer Self-Assessment, Sedex, SMETA, the Cool Farm Tool or crop-specific certifications. We will report on this annually through our Corporate Responsibility Report and Responsible Sourcing and Human Rights Milestones.

100% REUSABLE, RECYCLABLE OR COMPOSTABLE PACKAGING BY 2025 (BY VOLUME)

Kellogg Company is committed to working towards 100% reusable, recyclable or compostable packaging by the end of 2025. This builds on Kellogg’s current sustainable packaging commitment, as part of our Sustainability 2020 goals, to continue sourcing 100% recycled or certified sustainably sourced timber-based packaging. Sustainable packaging is one of three pillars in our global packaging strategy. We are embedding efforts to eliminate unnecessary plastic packaging by 2025 through priority programs, partnerships with suppliers, and engagement with other companies in platforms such as the Ellen MacArthur Foundation, the Consumer Goods Forum, and others to help accelerate transformational change for packaging materials.

Click here to download a full overview of our Better Days commitments and methodologies.